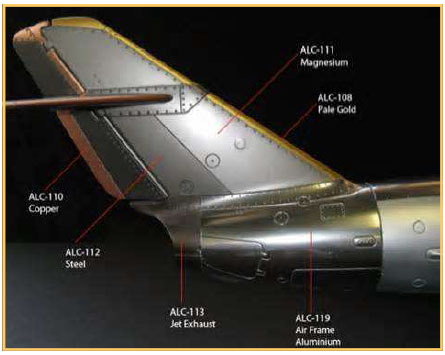

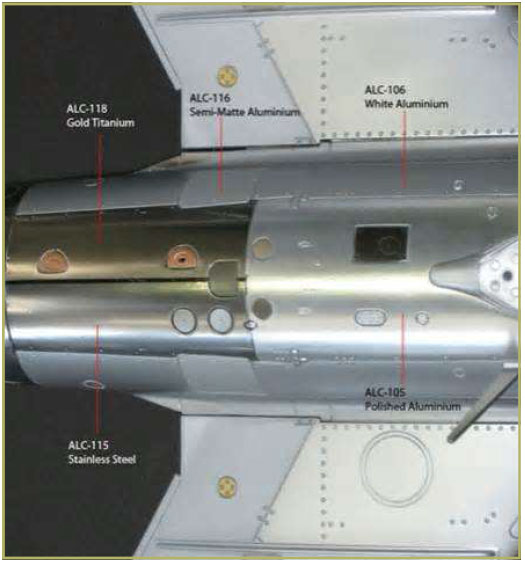

Alclad II Lacquer Natural Metal Finishes

By Bob King, Originally published June 2013

Alclad II is a cellulose based lacquer that dries almost instantly.

It has seventeen natural metal finishes, four

prismatic colors, three plastic base coat/

primers, and six transparent colors. It will

produce a wide range of realistic and durable

metal finishes on aircraft, cars, trucks, armor

and figures. It is pre-thinned for airbrush use

and no buffing is required.

A list of Alclad II finishes is as follows:

|

Natural Metal Finish (NMF):

- 101 Aluminum

- 102 Duraluminum

- 103 Dark Aluminum

- 104 Pale Burnt Metal

- 106 White Aluminum

- 108 Gold

- 110 Copper

- 111 Magnesium

- 112 Steel

- 113 Jet Exhaust

- 116 Semi-Matte Aluminum

- 117 Dull Aluminum

High Shine Shades: (translucent shades)

- 105 Polished Aluminum

- 107 Chrome

- 115 Stainless Steel

- 118 Gold Titianium

- 119 Airframe Aluminum

|

Prismatic Finishes:

- 201 Scarabeus blue-to-green

- 202 Maple Copper red-to-green

- 203 Jade green-to-gold

- 204 Sapphire deep blue-to-ultra violet/purple

Primer/Base coats:

- 302 Gray primer

- 303 Clear base

- 304/305 Gloss Black-2 & 4oz.

Transparent Colors:

- 400 Medium 401 Red

- 402 Yellow/Gold 403 Blue

- 404 Green 405 Black/Smoke

|

Important: One must prime the plastic

model before using Alclad II.

The primers protect the plastic from a crazed finish due to

microscopic weaknesses in the plastic surface. I have used

and recommend the following:

Tamiya Silver Leaf spray: The primer is very thin. It will

not cover any detail and looks like a very bright shiny aluminum.

Is also excellent primer base for panel shading with Alclad II transparent

smoke.

Tamiya Semi Gloss Black spray: This primer coat is also thin. It will

produce a finish that is not too shiny. It works well on the engine

portion of the fuselage to provide a contrast with the remainder

of the fuselage that has been primed with the above mentioned silver

leaf. It is also an excellent base for a radial engine. It seems

to add weight to the metal finish.

Alclad II Clear base: The manufacturer states that the new high shine

shade airframe aluminum looks very good over their primer. I have

tried it and it leaves a bright shine.

Gloss Black enamel: This is an excellent primer for high shine finishes

of chrome or highly polished metals since it traps most of the light

falling on it. Or for that matter any gloss black surface. The chrome

shade will only produce a robust finish when applied over a dark

gloss base coat. Their enamel base coat needs several days to cure

before applying the Alclad II shade.

Acrylic Auto Primer/Krylon: This works well on resin parts as well as

styrene plastic. Sand it with 1000/1200 wet/dry sandpaper. This

primer is very fragile. One should be careful not to sand through

to the bare plastic. This is really important if you are polishing

over an angle or raised surface. It is very hard to re-prime and

cover Alclad II on such a small area without having an inconsistent

finish.

Alclad II Gloss Black base: You should allow this primer

coat to dry 24 hours, It is very easy to use since it is already

thinned and ready to airbrush out of the bottle. It is surprisingly

transparent and it is often necessary to apply two coats for complete

coverage. It is very smooth.

Alclad II Gray primer/micro filler: This works well on hairline seams

that need filling. Allow 30 minutes to dry and sand it with micromesh

or ultra fine wet/dry sand paper.

Tamiya Gray/White primer: Be sure to sand the Tamiya primers with 1000/12000

wet/dry sandpaper. This comes out of a spray can and it is really

quick and easy.

Future Floor Finish: This should be allowed to dry completely. I would

not cover it with Alclad II for at least 24 hours. The longer you

can wait the better.

Krylon Gloss Black (a lacquered based spart paint): This is an old favorite.

You must allow it a full day to cure but it provides an excellent

base for a super high gloss finish. It does not go on ultra smooth,

so you should wet sand after it dries.

Caution! Alclad II is loaded with vapors that you should not

breathe over a prolonged period. Alclad II contains the

following: Normal Butanol, Methyl Ethyl Ketone, Methyl

Isobutyl Ketone,and Toluene.

Some Alclad II components are

highly flammable and can cause

slight to severe neurological, liver,

and kidney damage. Exercise more

than a modicum of caution when

using this product.

It is safe to handle and use with

proper precautions. So, use proper

precautions. Use adequate ventilation, in case of eye contact

rinse your eyes with water and if swallowed contact a

physician immediately. Keep out of reach of children.

When spraying with Alclad II use a multi-purpose

professional respirator with cartridges for organic vapors.

Before starting to airbrush, one should always shake the

bottle very well. I immediately shake each color just before

placing it in the airbrush. It really makes a difference.

One should look carefully at the primed surfaces for any

imperfections. If you find one, mask off the area and reprime

with several light coats. Sand until the surface is

perfect. Wipe the model to remove any fingerprints.

This really is important for a black gloss enamel surface that

will be sprayed with a chrome finish.

Alclad II Lacquer must be airbrushed on a surface that has

been primed and cleaned. I spray at 10-15 psi or less. I use a

gravity feed airbrush, so the low pressures work fairly well.

I seldom airbrush more than eight to ten drops at a time.

Apply the Alclad II at approximately a 45° angle or less to

the surface on your initial application. This will allow for a

thin coat that blends evenly across the surface. You should

spray one to two light coats, waiting one to two minutes

between coats. Alclad II will go a long way if you do not

waste it by using more than you need for each application.

When transferring Alclad II to your airbrush use a pipette.

Do not pour it into your airbrush since it is very hard to

control. Transfer less than you think you will need. Be sure

to recap the bottle immediately after using. (I prefer to use

about eight drops at a time.)

Prepare all small parts for your model that you want to

have a natural metal finish. This could include gun barrels,

wheels, radial engines, pilot tubes, etc. Then, after you

have finished spraying your primary surface, empty the

remaining paint in the airbrush on these small parts. I like

to use several shades on these parts for a unique finish.

Once it really looks good, set it aside. (You can do some of

your best work cleaning out the airbrush.)

One needs to guard against spillage by knocking over the

container. The containers are 1 3/16th inches in diameter

and three inches tall and made of glass.

The container must be secured, or it will spill. I use a

cluster of empty bottles in a larger container that serves as a

base. The empty bottles can be used to set pipettes in and

hold enough lacquer thinner for cleaning the airbrush.

You can accommodate different sized bottles by simply

removing or adding various bottle sizes until they wedge

themselves securely together.

One should save the empty glass bottles. They make an

excellent bottle to mix paint and thinner in and they are tall

enough to easily hold the long pipettes.

The best way to save Alclad II is to use less of it. The

darker the primer base, the more Alclad II is needed to

cover it.

I love using Tamiya’s Silver Leaf Spray, TS-30. It requires

only the lightest coat of Alclad II to achieve the desired

natural metal shade. Conversely, one can use Tamiya’s

Semi-Gloss Black, TS-29 as a base coat for Alclad II Jet

Exhaust, on a propeller.

You will use less Alclad II over primers that are closer to

the final shade you are trying to achieve. The exception to

this approach is the use of the High Shine Shades which

most often use a glossy black primer to optimize their

unique light absorbing qualities.

Before starting to spray your model, plan out the sequence

of colors that you want to use on the model. I prefer to use

two basic primer colors.

I first apply an

overall coat of

Tamiya Silver Leaf

TS-30. I then

determine where I

want a uniform

darker color. I mask

and spray that area

with Tamiya Semi-

Gloss Black TS-29.

I prefer to use these

primers because of

their durability and

fast drying time. They are dry to the touch in about 20

minutes, and they will not hide any of the detail on the

model. I then lightly buff the surface with an old t-shirt.

The old t-shirt is very soft and adds not a hint of lint

residue. This light buffing will

remove any primer that has not

adhered to the plastic.

The primers will set the basic

undertone for different areas of

the model. I have used many

variations that I will set forth in

the following section. It is really

fun to experiment with different

shading techniques.

Once your basic primer colors

are in place and you have

determined what shades you will

be using and where, start by

using the darkest shades first.

For example: Start with Steel (112 ), follow with

Magnesium (111), follow that with Duraluminum (102),

then Aluminum (101, then White Aluminum (106) lightly

airbrushed over all of the metal shades.

Alclad II dries fast and is very durable. After I have

applied each shade, I buff the application with a soft cotton

cloth. Next, mask the area and proceed to the next color.

Tamiya masking tape works extremely well over Alclad II.

It will not leave any residue and can be left on the surface for

months. Alclad II dries fast and is very durable.

After you have

finished applying

all of the various

shades, remove

all of the masks

from the natural

metal shades

exposing them

for a very light

coat of White

Aluminum.

This will “unify”

all of the panels and give the model an

overall consistent appearance. Next, you should highlight

the model with shades such as Pale Burnt Metal, Jet Exhaust,

and Transparent Smoke.

Aircraft use different sorts of metal with different grains that

affect the natural metal finishes appearance. By varying

these shades, your aircraft will appear more realistic. The

variations may be achieved several ways.

The panel is first

airbrushed with a coat

of gloss black and it is

followed with a

translucent coat of

Chrome (107). Next,

you spray the center of

the panel with a regular

shade of Aluminum

(101).

This shade is not translucent and therefore appears lighter in

color. After that, follow with another coat of translucent

Chrome(107). The result is variability in surface color.

The panel is first airbrushed with a coat of gloss black.

Then, the inner portion of the panel is sprayed with a glossy

gray. Once you have the black and gray glossy surface the

way you want it, spray the translucent Polished Aluminum

(105),Chrome(107), or Airframe Aluminum(119).

Pre-shade over the Tamiya Silver Leaf Spray TS-30 with any

of the Alclad II darker, regular shades. This is especially

useful when applying an exhaust or oil streak on an aircraft

fuselage. It is easier to cover the exhaust that you do not

want with subsequent applications of regular metal shades.

Transparent Smoke(405) is my favorite method of preshading

aircraft panels. It can be used to simulate a panel

that is not uniform in color or provide a slight contrast to a

nearby panel.

I prefer to use this method by a large margin. It is by far the

most economical way from a time and money standpoint.

Using the regular shades over the transparent smoke uses the

least amount of Alclad II and the finish possibilities are

almost limitless.

I first spray Tamiya Silver Leaf, TS-30, for the base primer

coat. The Alclad Transparent Smoke surface appearance is

somewhere between smoke and blue steel.

Shading is very easy to accomplish since it can be laid down

anywhere between transparent and opaque. It can also be

sprayed directly over the NMF Alclad II shade and then

recoated with another NMF Alclad shade.

It is very versatile. I have also painted with it over Tamiya,

Polly S, and Gunze

Sangyo acrylics and

then repainted over it

with Alclad II NMF

shades. It gives a very

nice effect.

Alclad II regular natural

metal shades may be

tinted with small

amounts of enamel or

auto acrylic. Tint only

the Alclad II that will

be immediately used.

Alclad II High Shine

shades should not be

tinted.

The transparent smoke may be applied so that the base coat

is almost translucent to an opaque blue, black cover. any of

One can use any of the regular shades or high shine shades

over the Silver Leaf and Transparent Smoke combination.

You also have the further option of using a regular shade

over this combination to achieve another variation. These

layers of Silver Leaf and Alclad II are so thin that you are

still able to achieve these effects without the appearance of

“out of scale” paint build up.

It is also easier to achieve the desired result by using your

airbrush to its best advantage. I believe that it is better to

gradually take away what you do not want on the surface,

rather than paint exactly what you want directly onto the

surface with an airbrush. It is especially true when doing

variations on a panel or rendering exhaust stains.

Seldom do I wait much more than ten minutes before

masking for the next shade application. I prefer to mask

with Tamiya masking tape. It has a razor sharp edge and it

holds its place when buffing against it.

I use Scotch 3M Scotch-Blue Painters Tape for Multi-

Surfaces to mask large areas. It is a medium-adhesive mask

that is not too expensive.

Note: When one is removing masking tape from an Alclad II

surface, be careful not to scratch the surface with a fingernail

or x-acto blade. The scratch will not cover with just a second coat

of Alclad II.

After a bit of practice, you do not even need to use masking

tape between panels. You can do a number of shades using

only a 3x5 card, damp paper, or a post-it note for a mask.

Testor’s Metalizer Finishing System does not require a

protective primer to be used over the styrene plastic.

It can be used to touch up an area that you may have sanded

through or created through a masking glitch.

Use it sparingly, but it

can really get you out of

some bad spots. It is

not as durable but it will

give you a beautiful

finish.

Painting over Alclad II

can be done with almost

any other paint. It is a

very good surface to

mask over and, if one is painting with an acrylic or enamel, it

can be removed without harming the original surface. The

acrylic paints adhere quite well to Alclad II. Tamiya acrylic

paints can be easily removed with Windex.

An ultra diluted mixture of Winsor & Newton’s Winton Oil Color Raw Umber and

lighter fluid works very well on Alclad II surfaces.

It should be applied before you clear coat the model for

decaling. If you are unhappy with the results of the panel

highlights, it easily wipes away showing no trace of being

applied. I prefer this solution because it is very subtle.

If it is necessary to remove Alclad II, Gunze Sango thinner

will remove Alclad II and its primer from styrene quickly

and easily without harming it.

This thinner is called Mr. Color Thinner. I call it the magic

elixir. It is an organic solvent that has many applications but

I think this is a really outstanding use for it.

Alclad II regular

metal shades can

be directly

decaled over.

Alclad II high

shine shades

should not be

directly decaled

over because

decal setting

solutions will

mar the finish.

I usually use a

clear coat before

decaling.

Airbrush the

clear coats for

the decals on ultra-light and polish them with 8,000/12,000

micromesh to place and protect them.

If you plan to model an aircraft that is dull and weathered,

use Tamiya Smoke (X-19) for the clear base coat. It is easily

applied and can be easily removed with a rag soaked in

Windex should you want to redo your results. The Alclad II

will not be affected by the Windex.

Prismatic colors should be applied over a glossy dark base.

Alclad Gloss Black Base or Tamiya Gloss Black TS-14 are

excellent base coats.

One should spray prismatic colors at 20 psi using a wide

spray pattern and a large tip. The metallic particles in the

prismatic colors are very large and require a large tip. Cover

the surface with as few passes as possible. The prismatic

colors will appear slightly rough when dry. This is normal.

Overcoat prismatic colors with two coats of clear to obtain a

deep

reflective

finish.

Alclad II is an

outstanding

way to do

natural metal

finishes for model aircraft.

[Editor’s note: Photos on this page courtesy of Alclad II/Tony Hipp.

All others courtesy of Bob King.]

Click here for more articles.

|